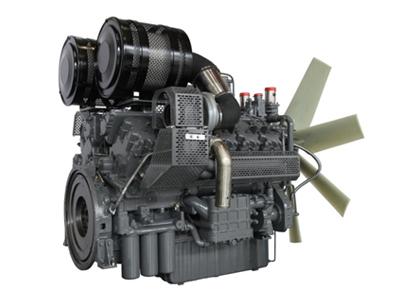

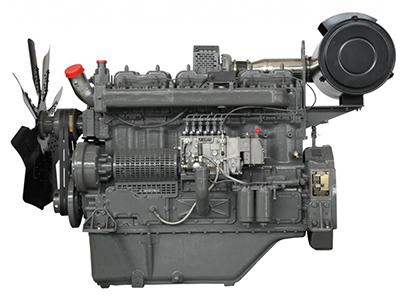

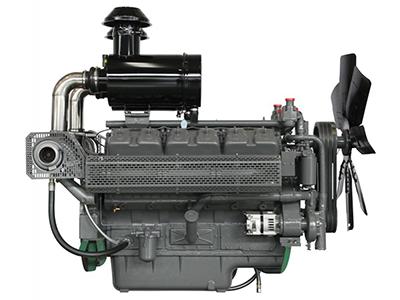

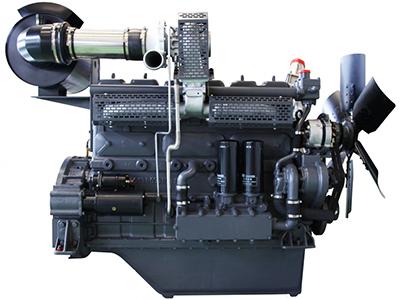

- Industrial Diesel Engine

- Power: 450/608kW

- rpm: 1500/1800

- Home

- High-speed Diesel Engines

- LANDI Series High-speed Diesel Engines (450~1338kW)

- LANDI 6-Cylinder In-Line High-speed Diesel Engine

LANDI 6-Cylinder In-Line High-speed Diesel Engine

Features

- Research & development based on AVL technology platform. CAE simulated analysis of the engine cylinder block, cylinder head, piston and other key parts.

- Every cylinder head is equipped with a cover to extend the diesel engine’s service life.

- A G POWER turbocharger and BOSCH fuel injection system are both used to improve the response speed, engine performance and service life, providing a quick supercharge within the working range.

- Intelligent electronic control system with a complete range of functions.

- The camshaft and roller rocker arms significantly improved the fuel economy and decrease friction levels.

- The new cooling and lubrication system use a double pump and double oil cooler structure to enhance the cooling performance.

- Low vibration and low noise.

- Standard flywheel housing/flywheel: SAE1#14’

Parameters

| Model | Cylinder Bore*Piston Stroke(mm) | Displacement (L) | Rated speed(r/min) | Rating(kW) | Minimum Fuel Consumption (g/kW.h) | Oil Consumption (g/kW•h) | Exhaust gas temperature(℃) |

| | 145×165 | 16.4 | 1500 | 430 | 196 | ≤0.48 | ≤650 |

| 145×165 | 16.4 | 1500 | 450 | 196 | ≤0.48 | ≤650 | |

| 152×165 | 18 | 1500 | 608 | 196 | ≤0.48 | ≤700 |

"*" Stands for average of SPL, based on GB/T2819-1995

Application

Wuxi Power Engineering Co., Ltd. (Wandi) has more than six decades of experience in large marine and land diesel engines. Known for quality, durability and reliability, we are committed to the idea that every component, piece and part of the engine contributes to the overall performance. As a leader of high speed power solutions in China, we are able to offer the most extensive of high speed engines for power generation. Wandi diesel engines are specially designed for marine applications, which are widely used by many boating and marine industry manufacturers.

Inquiry